The new 200i v3 Welding System is packed with features to give you more control, more capability, and a simpler welding process. The 200i v3 is the most advanced and capable micro TIG or Pulse Arc Welding system in the world. The 200i v3 has the widest range of power options, the most advanced features, and the most customizable weld. Guaranteed to simplify the welding needs of any jeweller, goldsmith, silversmith, dental technician or watchmaker.

How Does it Work?

Electrical Energy – Plasma Discharge

Micro TIG/Pulse Arc welding uses electrical energy to create a plasma discharge. The high-temperature plasma, in turn, melts metal in a small spot. This process takes place in milliseconds. The process is clean and very controllable – perfect for intricate and minute welding applications on precious and non-precious metals!. Filler metal can also be added to build up joints and create strong and reliable weld “beads”, or weld seams.

Two in One Combo

The Orion is a Micro TIG (also known as Pulse-arc) welder and a capacitive discharge resistance welder in one. This combination of abilities allows for infinite creative possibilities. In its "Arc Mode" (micro TIG/pulse-arc welding), the can be used to perform permanent welds, add metal, and do a variety of other amazing and time-saving applications. In its "Tack Mode" (capacitive discharge resistance welding), the can be used to temporarily position parts before welding or soldering.

Welding Capabilities

The unit can weld in a single fire mode meaning you have more control over the welds (one weld per 0.5 deconds), or you have the option for a rapid fire mode which allows you to weld up to 1-5 welds (4Hz). When choosing your desired power, the welder automatically chooses the welding mode suited to your job. At it's smallest, Pico Mode allows intricate welds as small as 0.01 Joules of energy, to achieve truly microscopic weld joints. At the highest, the Ultra mode allows for the maximum penetration on thicker, heavier jobs.

Basic Principle - How to use

- Attach The Grounding Clip

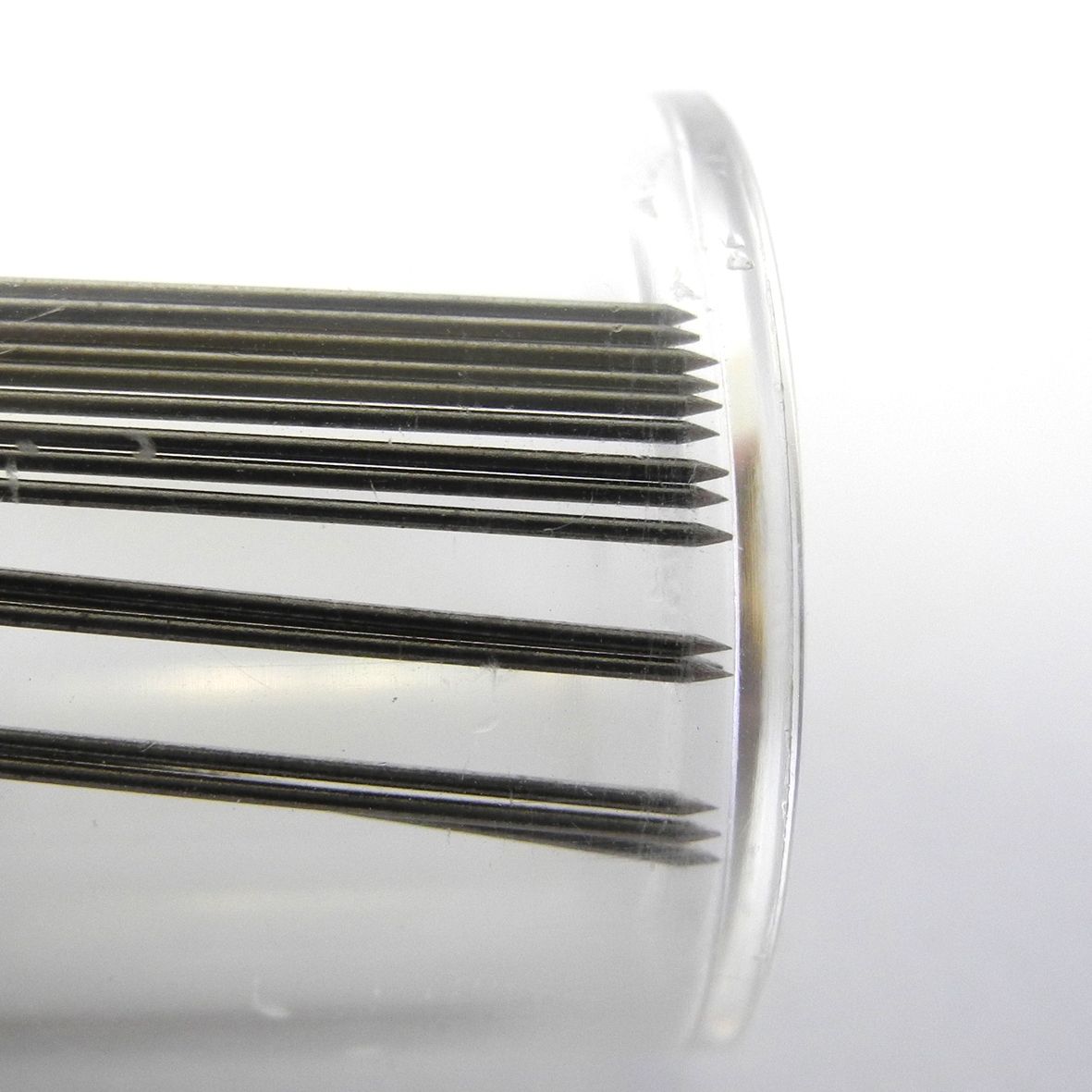

- Use the Specialized Microscope that is focused on the Welding Electrode Tip.

- Simply Touch the workpiece to the electrode and a weld is triggered.

- The Orion Welding system will Automatically adjust to your pressure and detect electrode liftoff.

- A Perfect Weld Every Time!

Perfect for:

• Ring Resizing • Filling Porosity • Seam Welding • Prong Re-Tipping

• Tack Pieces Together • Small Chains • Earring Posts • Eyeglass Repair

• Holloware • Jump Rings • Brooches • Watches • Bracelets • Pendents

• Wire Beading • And So Much More!

The Orion pulse welders are suitable for all welding applications in many trades including:

Dental - Dental laboratory technicians benefit in fabrication and reconstructive repair procedures, including new cast clasp assembly, loops and posts for tooth additions, cast extensions for existing partials, new wrought wire single-arm clasping, as well as many other common laboratory welding services. The weld produced is localised which is excellent for seam welding and eliminates thermal expansion on passive fit bridgework, implant bars and frames, and other common dental prosthetic connections. Suitable for most dental alloys including Titanium, Vitallium, Gold, Palladium and Platinum.

Jewellery - Delicate repair jobs such as re-tipping prongs can be done with ease and without the removal of stones, making the job in hand quick, efficient and very accurate. Welding heads to shanks can be done with the ease and eliminates much cleaning up afterwards. Platinum ring sizing can be done without leaving the dark grey line as is usually found when soldering with traditional methods. The Orion pulse welders enable you to repair almost all types of jewellery on site which adds a massive benefit to your services offered to your clients.

Horology - When refurbishing or repairing watches, case and bracelet repairs can be done on gold, stainless steel or bi metal bracelets with ease. Obsolete parts that have been damaged or broken can be welded together avoiding expensive replacement parts and long waiting times for both you and your customers. Steel clock parts that have been cracked such as mainsprings can be strengthened with the laser.

PLEASE NOTE: These units need a PURE ARGON gas supply which you can purchase from https://www.albeegascylinders.com. We recommend AlBee cylinders as they have a built-in gas flow regulator and are compatible with our Orion welders in conjunction with a 6mm push fit fitting. The AlBee Argon cylinders are also RENT FREE so you don't have to worry about expensive rental costs from other suppliers.